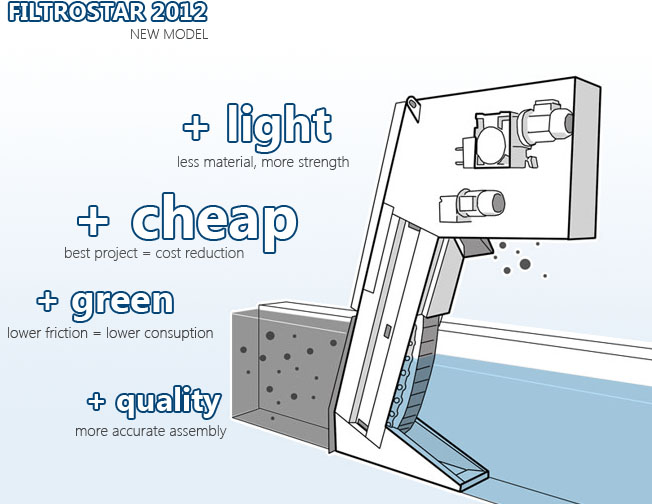

Self-cleaning, continuous belt screen FILTROSTAR MY 2012

Designed to remove suspended solids from sludge. FILTROSTAR is an automatic fine screen suitable for installation in conduit or containment tank. It features self-cleaning continuous filter tape made of a dense mesh of

profiled elements capable of conveying the material retained until the expulsion section at the top of the machine.

FILTROSTAR consists essentially of a frame within the filter belt slides on guide rails. This belt separates solids in suspension from the sludge and conveys them to the top of the machine.

Here, particular shape of filtering elements perform a self-cleaning action during the inversion motion of the belt. The self-cleaning action is made more effective by use of a counter-rotating brush, placed in the outlet point.

The solids in this way will fall by gravity into a tank, in a press or on a conveyor belt.

Filtrostar screen has a higher flow rate and it is also suitable for clean water containing elongated fibers.

USE SECTORS

- Civil and industrial purification plants- Tanning or Food Industry

- Paper Mills

- Slaughterhouses and Livestock farms

TYPES OF GRID

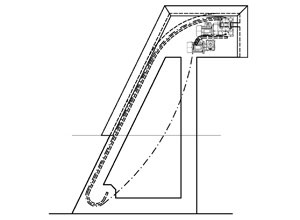

Easy to install, requires no anchorage because it is simply supported at the bottom of the channel.

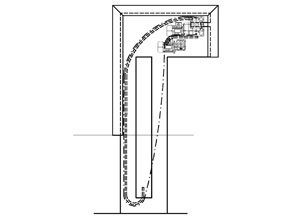

Particularly suitable where space is limited. The screen is fixed on the channel sides with appropriate supports.

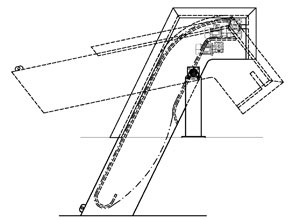

It is supported on the top by two structures fixed on the channel sides. The screen can be rotated completely out of the channel for cleaning and maintenance. So there's no need of bypass channel.

PATENTED CLEANING ELEMENT

The cleaning element is designed to prevent clogging of the belt. It's made of special plastic material with high resistance to wear, acid and heat.

Filtration degree: 1 - 3 - 6mm. Other spacings available on request.

DRIVE SYSTEM

The motor drive, installed in a lateral position, is directly keyed on the shaft which acts on the rollers at the extremities of the belt support shafts. To avoid damage, an electronic torque limiter stops the machine when a clogging is detected.

FRAME

The new concept support frame is characterized by a special shaping of reinforcement, which allows to reduce the thickness, containing costs for the material but at the same time increasing the strength. It is made of AISI 304 stainless steel.

SAFETY PROTECTION

AISI 304 stainless steel carter is fixed on the support structure, to protect all moving parts of the top portion of the screen, according to the 2006/42/CE Machinery Directive. The machine is equipped with user manuals and CE certification.

OPTIONS

- AISI 316 stainless steel frame.- Mechanical torque limiter.

- Electric control and monitoring.

Gallery.

Italiano

Italiano English

English